Your reliable industrial supplier

Full Manufacturing Capabilities

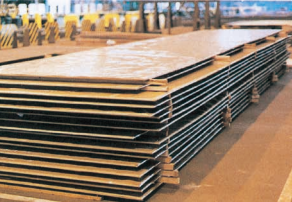

Special Alloy offers steel alloy to produce high quality steel plate and tube customize products.

Custom Steel Produce

Special Alloy provides customized metal materials in various sizes and shapes to meet the needs of different uses

Professional team

We are equipped with a professional technical team and sales and after-sales team to connect with customers

Special Alloy – Professional Steel Factory in China

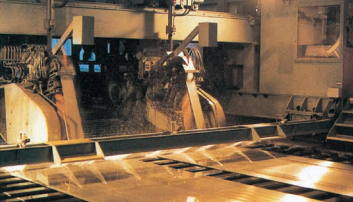

Special Alloy offers steel fabrication services for producing different products, structures, and parts. We provide a variety of fabrication processes including cutting, welding, stamping, bending, assembly, laser cutting, and more. Our engineers are skilled in bending, folding, and cutting different steel materials to form any shape.

We are equipped with advanced steel fabrication equipment such as chop saws, band saws, and other tools that are essential for cutting and shaping steel materials.

Special Alloy also has world-class press brakes which enable us to create sharp angles and bends on steel sheets. Our steel fabrication services are suitable for various industries such as aerospace, automotive, and construction.

At Special Alloy, we offer custom steel fabrication services. Our steel products include steel sheets, steel tubes, and coils. Choose Special Alloy as your steel manufacturer for all your fabrication needs!”

Custom Any Metal Parts for Your Project

Special Alloy has full capabilities in customizing any Alloy metal parts through our fabrication services. We can manufacture according to your specific designs, shapes, sizes, surface finishes, thicknesses, and more. Our engineers can customize your orders through the following services and processes:

- We use Analytical balance, spectrometer selection Raw material

- Electric furnaces are used to heat the raw material

- Hydraulic or mechanical presses and hammers are used to form

- The forged parts are heated to a specific temperature and cooled

- CNC machines are used for precision machining

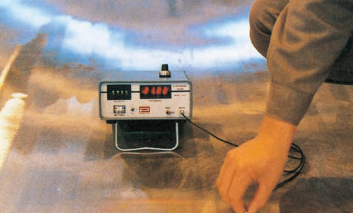

- Non-destructive testing and ultrasonic testing and inspection

Aside from that, Special Alloy is also an expert in sheet metal assembly, burning, hole punching, drilling, shearing, and more.

What We Can Offer?

Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

We make it easy to find the detailed product information

Our Digital Services

OEM & ODM Available

Whether you want to have your logo engraved on the coconut bowl or want to design it differently, we can help you.

Lighting Fast Delivery

If you don’t need additional designs, just the finished product, we have the inventory to support fast delivery.

Start With Low MOQ

If you want to wholesale coconut bowls, we support a minimum order quantity for the first order.

Why Choose Special Alloy? Competitions

Our natural coconut bowls have passed the CE, FDA and other approval, and we have 12 years of experience in making coconut shell bowls. Our products are eco-friendly, and they use the most advanced technology to produce.

Reliable partner

For over 20 years, Industeel has supplied 300,000+ tons of steel products globally to top companies in the Oil and Gas, chemical, and nuclear sectors.

Tailor made solutions

Orders can be any size, and we can customize material and production for the most demanding requests. Industeel can also make 3-layer clad plates.

Gage of quality

Industeel offers high-quality steel for backing and cladding with custom corrosion resistance and bonding. Quality is assured through 100% ultrasonic and shear testing.

Demanding Quality Assurance

Certifications: ISO 9001, ISO 14001 and OHSAS 18001, BV, Lloyd’s, TÜV.

International Routes Ticket available Now for online.

PROVIDING THE HIGH QUALITY SERVICES

At our company, providing high-quality services is our top priority. With exceptional expertise, outstanding customer service, competitive pricing, cutting-edge technology, quick turnaround time, and customized solutions, we deliver superior services that meet our customers’ unique needs

- Exceptional durability: Our products are built to last.

- Superior strength: Our products are stronger than the competition.

- Unmatched reliability: Our products perform consistently over time.

- High-quality materials: We use only the finest materials in our products.

- Consistent quality: We maintain strict quality control standards to ensure consistent product quality.

- Precise manufacturing: Our products are manufactured with the highest level of precision.

- Rigorous testing: Our products undergo rigorous testing to ensure quality and safety.

- Expert engineering: Our products are engineered to the highest standards by our team of experts.

Client Testimonials

FAQ

A Steel coil is a flat metal sheet wound into a roll. It is commonly used in various applications, including construction, automotive manufacturing, and appliance production.

Steel structures are used in construction for their durability and strength. They are commonly used in the building of bridges, high-rise buildings, and industrial facilities.

Cylinders are used in hydraulic systems to generate force. They offer several advantages, including high power density, precise control, and long service life.

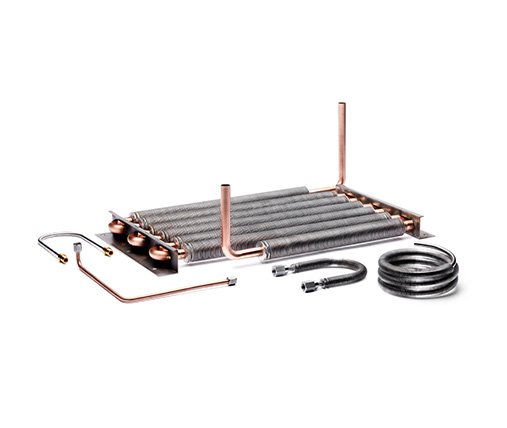

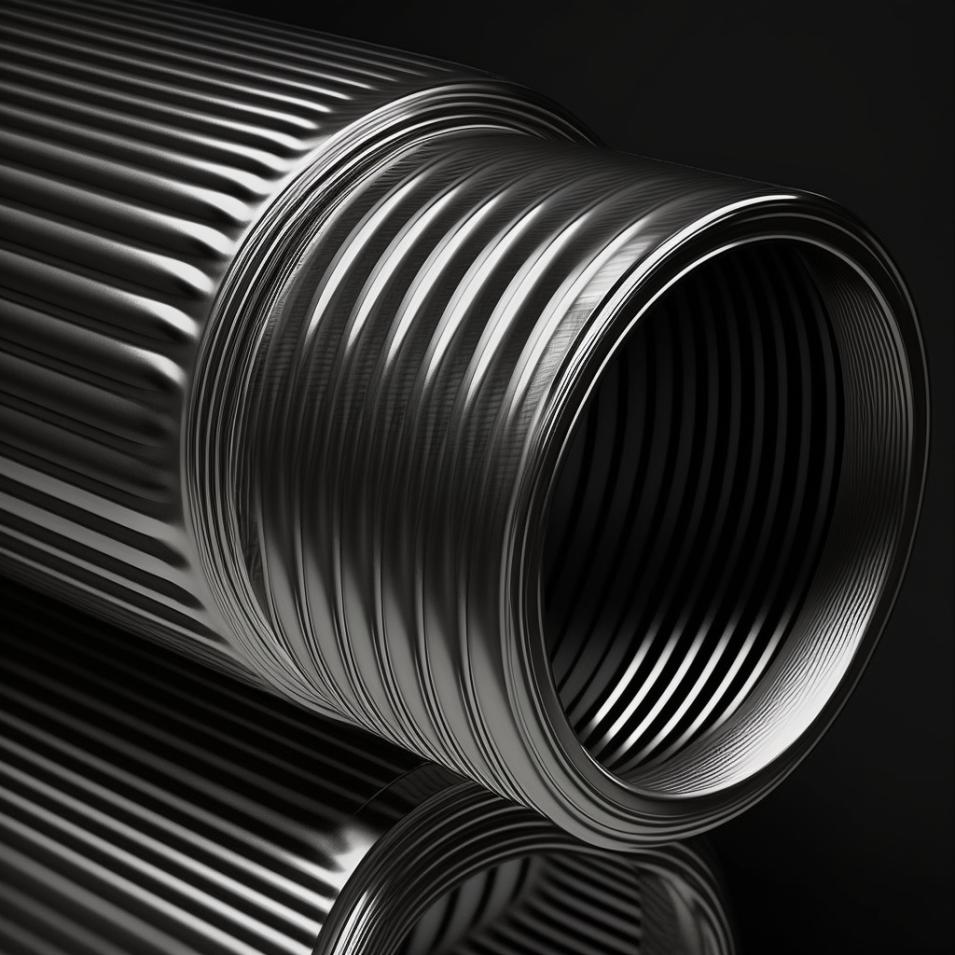

Finned tubes are heat exchanger tubes with fins on the outside. They are used to increase the heat transfer rate between the fluid inside the tube and the surrounding air or fluid.

Clad plates are composite plates made of two or more layers of different metals or alloys. They are used in various industries, including chemical processing, power generation, and marine engineering.

Clad Heads provide a cost-effective alternative to using solid metal heads, while maintaining the required strength and durability. They are commonly used in the manufacturing of pressure vessels.

Yes, Steel structures can be customized to fit specific project requirements. This includes the design, size, and shape of the structure.

Finned tubes are typically made of materials such as copper, aluminum, or stainless steel. The fins are usually made of the same material as the tube, but can also be made of other materials such as brass or nickel.

The bonding in a clad plate is achieved through a process called explosive welding or roll bonding. Quality standards for clad plates vary by industry, but generally involve testing for bonding strength and dimensional accuracy.